Asphalt Mixer Mixing Arm

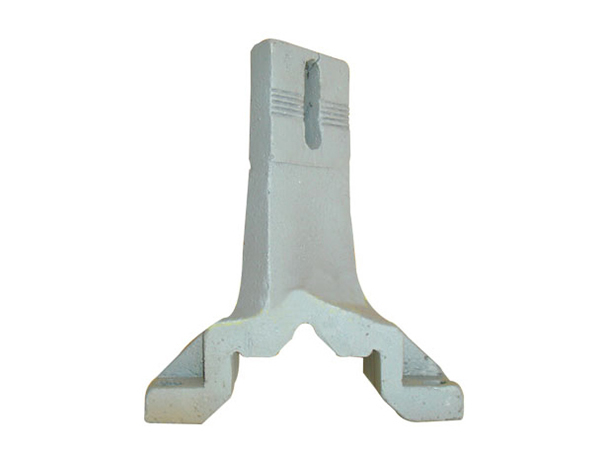

Names: Mixing Arm, Paddle Arm

Materials: Nodular cast iron or casting steel

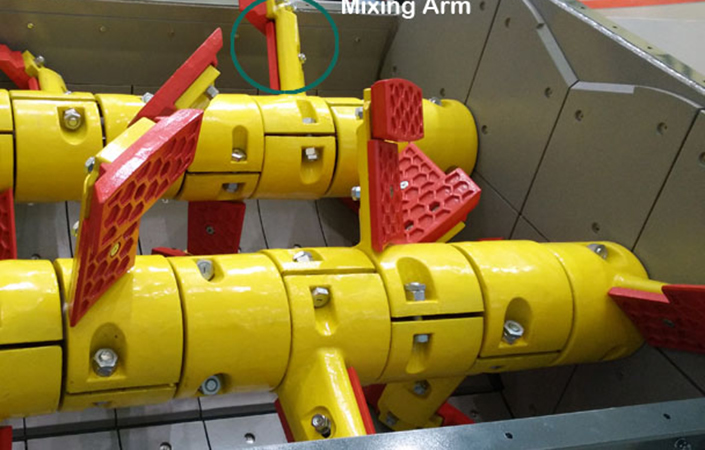

Applicable mixers: Twin shaft mixer, pan mixer, planetary mixer, vertical mixer, concrete mixer, Asphalt mixer, etc. of various brands

Customizable or not: Customizable; tailor made to customers' drawings or samples

Applications: As one of the essential asphalt plant replacement parts, the mixing arm is ideal for different mixers and mixing plants.

Technology: Mould casting

Service life: Enough time for about 200,000 CBM asphalt

Packaging details: Composite material box

Delivery cycle: 35 days; Ex-stock available

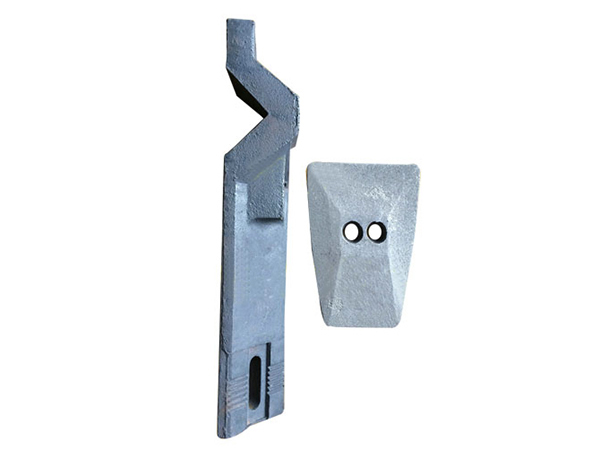

Mixing Arm Structure

As an acknowledged leader in mixing plant parts, Casting parts is now able to manufacture replacement mixing arms for the asphalt plants in a vast variety of brands including AMMANN, MARINI, SPECO, PARKER, LINTECH, LINHOFF, ASTEC, BENNIGHOVEN, SANY, ZOOMLION, NFLG, CA-LONG, TTM, XCMG, HUATONG, DG, ROADY, XRMC, XUETAO, XITONG, etc.

- Mixing arm for ACP3000 and ACP4000 asphalt plants

- Mixing arms for SPECO TSAP-800, TSAP-1000 and TSAP-1300 asphalt plants

- Mixing blade, mixing arm and liner plate for LB asphalt plant

-

Mixer arm for XCMG LB3000 asphalt plant

- Mixer arms for XCMG 240, 320, LB2000 and LB3000 asphalt plants

- Mixing arms for DG3000 asphalt plant

- Mixing arms for XITONG QLB2000 and QLB3000 asphalt plant

- Mixing arm for LINTEC320 asphalt plant

- Mixing arm for MARINI 320 asphalt plant

- Mixing arm for BENNIGHOVEN asphalt plant

| Hardness | 52-62HRC |

| Life | More than 200,000 cubic meter concrete or 300,000 tons asphalt |

| Materials | High chromium cast iron/steel |

| Standards | CN:KM TB Cr 15-25-GTUS:ASTM A532 Class Two Type D |

| Extension strength | 380 N/mm2 |

| Elongation at break | 1% |

| Shock impact (resistance) value | >5 ak N.M/CM2 |

| Flexural strength | >600 ak N.M/CM2 |

| Certifications | ISO9001:2008, CE |

| Metallographic organization | M+M7C3+M23C6 |

| Process | Lost Foam Casting |

Chemical Compositions

| Name | Chemical Compositions % | Hardness | ||||||||

| C | P | S | Si | Mn | Cr | Ni | Mo | Cu | ||

| Special high chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 22 | <1 | <1 | <0.5 | 62 |

| High chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 15 | <0.5 | 52 | ||

| Low chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 3 | 48 | |||

| High manganese steel | 1.2 | <0.06 | <0.06 | 16 | 45 | |||||

| Alloy steel casting | 1.2 | <0.06 | <0.06 | 2 | 1 | 45 | ||||